20 Ton Overhead Cranes, Single Girder or Double Girder Design

Single girder & double girder Overhead Crane 20 ton for sale. Which is better for you,20 ton overhead crane with single girder or double grider crane design?

Category: 20 Ton Overhead Crane

Your Trusted 20 Ton Overhead Cranes Manufacturer & Supplier

20 Ton Overhead Cranes, Single Girder & Double Girder Crane Design

Which is Better for You, 20 Ton Overhead Crane with Single Girder or Double Grider Design?

Single girder & double girder Overhead Crane 20 ton for sale. Which is better for you,20 ton overhead crane with single girder or double grider crane design?

Single Girder or Double Girder for Your 20 Ton Overhead Crane

In the industrial sector of industrial equipment, every component plays a pivotal role in ensuring smooth operations and efficient workflow. Among these, the overhead crane stands tall, quite literally, as a vital asset in numerous industries. But when it comes to selecting the right overhead crane for your needs, particularly one with a 20 ton capacity, the decision becomes paramount. Welcome to our guide, where we shed light on the critical choice between a single girder and a double girder design.

The selection of the appropriate crane design isn't just about aesthetics; it's about functionality, safety, and ultimately, cost-effectiveness. A 20 ton overhead crane is a significant investment, and choosing the wrong design can lead to inefficiencies, downtime, and even safety hazards. Therefore, understanding the nuances between single girder and double girder designs is crucial for making an informed decision.

So, what exactly are single girder and double girder overhead cranes? What sets them apart, and how do you determine which one is best suited for your needs? These are the questions we'll delve into throughout this guide. By providing a comprehensive overview of both designs, comparing their features, applications, and considerations, we aim to empower you to make a choice that aligns seamlessly with your operational needs and goals. Stay tuned as we embark on this journey of exploration and discovery in the world of overhead cranes.

Single Girder 20 Ton Overhead Cranes

Single girder 20 ton overhead cranes for sale. Let check the main structrue of 20 ton overhead crane with signle girder design. Simply put, these cranes are designed with a single horizontal beam, or girder, spanning the width of the crane bridge. This singular girder bears the weight of the hoist and the load, providing the structural support necessary for lifting and moving heavy objects.

Characterized by their simplicity and efficiency, single girder cranes are renowned for their versatility across a wide range of applications. From warehouses to manufacturing facilities, these cranes offer a cost-effective solution for handling moderate to heavy loads with precision and ease.

Key Components and Structure

The main parts and cmponents of a single girder 20 ton overhead crane typically consists of several essential components. At its core lies the girder itself, reinforced to withstand the imposed load. Suspended from the girder is the hoist, which serves as the primary lifting mechanism. Additionally, end trucks equipped with wheels facilitate the horizontal movement of the crane along the runway beams.

The streamlined design of single girder cranes ensures optimal functionality while minimizing unnecessary complexities. This simplicity not only enhances operational efficiency but also simplifies maintenance and repairs, contributing to overall cost savings.

Features of 20 Ton Electric Hoist of Single Girder Overhead Crane

The 20 ton electric hoist used in single girder overhead cranes offers several key features to ensure efficient and safe lifting operations. Here are some common features you can expect:

- High Load Capacity: The 20 ton electric hoist is designed to handle heavy loads up to 20 tons, making it suitable for a wide range of industrial applications.

- Compact Design: Single girder overhead cranes often incorporate compact electric hoists, allowing for efficient use of space in the facility.

- Variable Speed Control: Many electric hoists come equipped with variable speed control, allowing operators to adjust lifting and lowering speeds based on the specific requirements of the load and application.

- Smooth and Precise Operation: Electric hoists provide smooth and precise lifting and lowering motions, enabling accurate positioning of loads with minimal sway or jerking.

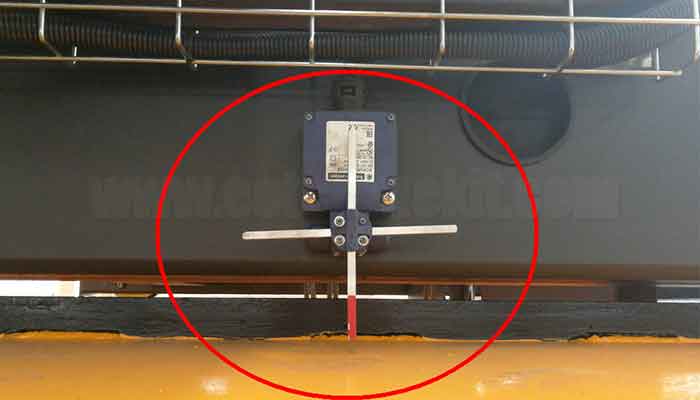

- Safety Features: Electric hoists are equipped with various safety features to ensure safe lifting operations. These may include overload protection, emergency stop buttons, and limit switches to prevent over-travel.

- Remote Control Option: Some electric hoists offer remote control capabilities, allowing operators to control the hoist from a safe distance, further enhancing safety and convenience.

- Durable Construction: Electric hoists are typically constructed from high-quality materials to withstand the rigors of industrial environments and provide reliable performance over time.

- Easy Maintenance: Electric hoists are designed for easy maintenance, with accessible components and service points for routine inspections, lubrication, and repairs.

- Compliance with Standards: Electric hoists are manufactured to meet or exceed industry standards and regulations for safety and performance, ensuring compliance with relevant requirements.

- Customization Options: Manufacturers may offer customization options to tailor the electric hoist to specific application requirements, such as specialized hooks, lifting attachments, or control systems.

Overall, the 20 ton electric hoist used in single girder overhead cranes combines robust performance, safety features, and versatility to meet the demanding lifting needs of industrial operations.

Various Configurations of Single Girder 20 ton Overhead Cranes

Single girder 20 ton overhead cranes come in various configurations to meet a wide range of lifting needs and operational requirements. Here are some common configurations:

Standard Single Girder Crane Economical 20 Ton Bridge Cranes:

Features a single horizontal beam (girder) running along the length of the crane bridge.

Provides efficient lifting and movement of loads up to 20 tons.

Suitable for general-purpose lifting applications in manufacturing, warehouses, and workshops.

European-style Single Girder 20 Ton Overhead Crane:

Incorporates a lightweight and modular design with European-style components and features.

Offers precise and efficient lifting operations with smooth travel and minimal sway.

Ideal for applications requiring high-speed and precise load positioning, such as assembly lines and manufacturing facilities.

Low Headroom Single Girder Overhead Crane 20 Ton:

Designed with a reduced headroom profile to maximize hook height in facilities with limited vertical space.

Offers optimal clearance for lifting taller loads while minimizing the distance between the crane and the ceiling.

Suitable for installations in buildings with low ceilings or overhead obstructions.

Customized 20 Ton Single Girder Bridge Crane with Duel Hoists :

Can be customized to meet specific application requirements, such as specialized lifting attachments, control systems, or environmental conditions.

Tailored to accommodate unique operational constraints and lifting needs, providing a bespoke lifting solution for diverse industries.

These configurations offer flexibility and versatility, allowing businesses to choose the most suitable single girder 20 ton overhead crane for their specific lifting requirements and operational constraints.

Advantages and Disadvantages

Like any equipment, single girder 20 ton overhead cranes come with their own set of pros and cons.

Advantages:

Cost-Effective: Single girder cranes typically have lower manufacturing and installation costs compared to their double girder counterparts.

Compact Design: The single girder configuration results in a more compact overall profile, making these cranes ideal for facilities with limited space.

Versatility: With their ability to handle a diverse range of loads, single girder cranes offer flexibility across various industrial applications.

Disadvantages:

Limited Load Capacity: While suitable for moderate to heavy loads, single girder cranes may not be as well-suited for exceptionally heavy loads as double girder designs.

Reduced Hook Height: The single girder configuration may result in a lower hook height compared to double girder cranes, limiting vertical lifting capacity in some instances.

Double Girder 20 Ton Overhead Cranes

Double girder 20 ton overhead cranes represent a robust and sturdy solution for heavy lifting applications. Unlike their single girder counterparts, these cranes feature two horizontal beams, or girders, spanning the width of the crane bridge. This dual girder configuration provides enhanced stability and load-bearing capacity, making them well-suited for handling heavier loads with precision and reliability.

Characterized by their robust construction and impressive lifting capabilities, double girder cranes are commonly utilized in industries where heavy-duty lifting operations are the norm. From steel mills to shipyards, these cranes excel in environments where strength, durability, and performance are paramount.

Key Components and Structure

The structure of a double girder 20 ton overhead crane is designed to withstand the rigors of heavy lifting operations. At its core are the two parallel girders, engineered to distribute the load evenly and minimize deflection. Suspended from these girders is the hoist, which serves as the primary lifting mechanism, offering precise control and maneuverability.

Additional components such as end trucks, runway beams, and electrical systems contribute to the overall functionality of the crane, ensuring smooth operation and safety during lifting operations. The robust construction of double girder cranes makes them suitable for handling exceptionally heavy loads with ease and efficiency.

Features of 20 Ton Electric Hoists for Double Girder Overhead Cranes

The 20 ton electric hoists used in double girder overhead cranes offer a range of features tailored to meet the demands of heavy-duty lifting applications. Here are some common features you can expect:

- High Load Capacity: The 20 ton electric hoist is engineered to lift and move heavy loads weighing up to 20 tons, making it suitable for a wide range of industrial tasks.

- Dual Girder Compatibility: Designed specifically for use with double girder overhead cranes, the electric hoist is equipped to handle the increased load-bearing capacity and stability provided by the dual girder configuration.

- Robust Construction: Built with durable materials and components, the electric hoist is engineered to withstand the rigors of industrial environments and provide reliable performance over an extended lifespan.

- Variable Speed Control: Many electric hoists feature variable speed control capabilities, allowing operators to adjust lifting and lowering speeds to match the specific requirements of the load and application.

- Smooth and Precise Operation: Electric hoists deliver smooth and precise lifting and lowering motions, facilitating accurate positioning of heavy loads with minimal sway or jerking.

- Safety Features: Electric hoists are equipped with a range of safety features to ensure safe lifting operations. These may include overload protection, emergency stop buttons, and limit switches to prevent over-travel.

- Remote Control Option: Some electric hoists offer remote control capabilities, enabling operators to control the hoist from a safe distance, further enhancing safety and convenience.

- Easy Maintenance: Electric hoists are designed for ease of maintenance, with accessible components and service points for routine inspections, lubrication, and repairs.

- Compliance with Standards: Electric hoists are manufactured to meet or exceed industry standards and regulations for safety and performance, ensuring compliance with relevant requirements.

- Customization Options: Manufacturers may offer customization options to tailor the electric hoist to specific application requirements, such as specialized hooks, lifting attachments, or control systems.

Overall, the 20 ton electric hoists for double girder overhead cranes combine robust performance, safety features, and versatility to meet the demanding lifting needs of heavy-duty industrial operations.

Various Configurations of double girder 20 ton overhead cranes

Double girder 20 ton overhead cranes are available in various configurations to suit different lifting requirements and operational environments. Here are some common configurations:

Top Running Double Girder Crane with Electric Hoist Trolley :

The most common configuration, where the bridge runs on top of the runway beams.

Provides maximum hook height and lifting capacity.

Suitable for applications where headroom is not a constraint.

Open Winch Double Girder 20 Ton Bridge Crane:

Utilizes an open winch hoisting mechanism mounted on the bridge.

Provides higher lifting speeds and precise load control.

Ideal for applications requiring frequent and precise load positioning.

Low Headroom Double Beam Overhead Crane 20 Ton :

Designed with a reduced headroom profile for use in facilities with limited vertical space.

Offers optimal hook height and lifting capacity within restricted headroom constraints.

Grab Bucket Double Girder Crane 20 Ton:

Equipped with a grab bucket attachment for handling bulk materials such as sand, gravel, or scrap metal.

Provides efficient loading and unloading of materials in bulk handling applications.

Magnet Overhead Crane with Double Girder Crane Design 20 Ton :

Fitted with a magnet attachment for lifting and transporting ferrous materials such as steel plates or coils.

Offers quick and efficient material handling in metal fabrication and steel processing industries.

Explosion-Proof Crane with Double Girder Design 20 Ton :

Designed with special features to prevent sparking or ignition in hazardous environments with flammable gases or dust.

Complies with strict safety regulations for use in potentially explosive atmospheres.

These are just a few examples of the various configurations available for double girder 20 ton overhead cranes. Each configuration offers unique features and benefits, allowing businesses to choose the most suitable crane for their specific lifting requirements and operational constraints.

Advantages and Disadvantages

As with any equipment, double girder 20 ton overhead cranes come with their own set of advantages and disadvantages.

Advantages:

High Load Capacity: Double girder cranes are capable of handling significantly heavier loads compared to single girder designs, making them ideal for heavy-duty lifting applications.

Increased Hook Height: The dual girder configuration allows for a higher hook height, providing greater vertical lifting capacity and clearance for taller loads.

Enhanced Stability: The structural integrity of double girder cranes provides enhanced stability and control, particularly when handling large and bulky loads.

Disadvantages:

Higher Cost: Double girder cranes typically involve higher manufacturing and installation costs compared to single girder designs, making them a substantial investment.

Larger Footprint: The dual girder configuration results in a larger overall footprint, requiring more space for installation and operation compared to single girder cranes.

While double girder 20 ton overhead cranes offer unparalleled strength and performance, it's essential to weigh these advantages and disadvantages against your specific operational requirements. In the next section, we'll delve deeper into the comparison between single and double girder designs to help you make an informed decision. Stay tuned as we continue our exploration of overhead crane solutions.

Differences Between Single Girder and Double Girder 20 Ton Overhead Cranes

Load Capacity Handling Capabilities

One of the most significant distinctions between single girder and double girder 20 ton overhead cranes lies in their load capacity handling capabilities. While both designs are capable of lifting substantial loads, double girder cranes typically excel in this regard. With their robust construction and dual girder configuration, double girder cranes boast higher load capacities compared to their single girder counterparts. This makes them the preferred choice for industries and applications that demand the handling of exceptionally heavy loads with precision and efficiency.

Span and Height Requirements

When it comes to span and height requirements, both single and double girder cranes can be tailored to meet specific operational needs. However, there are some notable differences between the two designs. Single girder cranes are often favored for their compact design, making them ideal for facilities with limited space or lower ceiling heights. On the other hand, double girder cranes typically require more vertical clearance due to their higher hook height, making them better suited for applications where taller loads need to be lifted or where greater lifting heights are necessary.

Structural Differences and Implications

Structurally, single and double girder cranes differ in their design and construction, which has implications for their performance and capabilities. Single girder cranes feature a simpler design with a single horizontal beam spanning the width of the crane bridge. While this design offers versatility and cost-effectiveness, it may not provide the same level of stability and load-bearing capacity as double girder cranes. Double girder cranes, with their dual girder configuration, offer enhanced stability and structural integrity, allowing them to handle heavier loads with greater precision and control.

Operational Considerations

In terms of operational considerations, both single and double girder cranes have their unique advantages and challenges. Single girder cranes are known for their simplicity and ease of operation, making them well-suited for a wide range of applications. They require less maintenance and are generally more cost-effective to operate. However, double girder cranes offer superior performance and control, particularly when it comes to handling heavy loads or operating in demanding environments. They may require more maintenance and upkeep, but their robust construction ensures reliable operation even under the most challenging conditions.

Cost Differences

Cost is a crucial factor to consider when choosing between single and double girder 20 ton overhead cranes. While single girder cranes typically have lower upfront costs and may be more economical for smaller-scale operations or budgets, double girder cranes offer superior performance and load-handling capabilities, albeit at a higher initial investment. It's essential to weigh the long-term benefits and cost savings against the upfront expenses to determine the most cost-effective solution for your specific needs and requirements.

These differences is key to making an informed decision when selecting between single and double girder 20 ton overhead cranes.

Applications and Suitability

Industries and Applications where Single Girder Designs Excel

Single girder 20 ton overhead cranes are well-suited for a variety of industries and applications due to their versatility and cost-effectiveness. Some industries where single girder designs excel include:

- Warehousing and Distribution: Single girder cranes are commonly used in warehouses and distribution centers for lifting and moving goods and materials with efficiency and precision.

- Manufacturing: In manufacturing facilities, single girder cranes are often employed for tasks such as assembly, material handling, and loading/unloading operations.

- Light to Medium Industrial Applications: Single girder cranes are ideal for light to medium-duty lifting tasks in industries such as automotive, aerospace, and electronics manufacturing.

Industries and Applications where Double Girder Designs Excel

Double girder 20 ton overhead cranes are favored in industries and applications that require heavy-duty lifting capabilities and superior performance. Some industries where double girder designs excel include:

- Steel Mills and Metal Fabrication: Double girder cranes are well-suited for handling heavy metal components and materials in steel mills, foundries, and metal fabrication facilities.

- Shipbuilding and Ports: In shipyards and port facilities, double girder cranes are essential for lifting and moving large ship components and containers with precision and reliability.

- Heavy Machinery Manufacturing: Industries involved in the production of heavy machinery and equipment rely on double girder cranes for lifting and maneuvering oversized components and assemblies.

Factors Influencing the Choice Between the Two Designs

Several factors influence the choice between single and double girder 20 ton overhead crane designs:

- Load Capacity Requirements: The weight of the loads being lifted is a crucial factor in determining the appropriate crane design. Double girder cranes are better suited for handling heavier loads compared to single girder designs.

- Span and Height Requirements: The required span and lifting height of the crane play a significant role in selecting the appropriate design. Single girder cranes may be preferred for applications with limited space or lower ceiling heights, while double girder cranes offer greater lifting heights and clearance.

- Operational Environment: Considerations such as the frequency of use, operational conditions, and environmental factors (e.g., temperature, humidity) can influence the choice between single and double girder designs.

- Budget Constraints: Budgetary considerations are essential when selecting an overhead crane design. While single girder cranes typically have lower upfront costs, double girder cranes offer superior performance and load-handling capabilities, albeit at a higher initial investment.

By carefully evaluating these factors and considering the specific requirements of your industry and applications, you can make an informed decision when choosing between single and double girder 20 ton overhead crane designs. In the next section, we'll explore the performance and efficiency aspects of both designs to provide further insights into their suitability for different applications. Stay tuned as we continue our exploration of overhead crane solutions.

Performance and Efficiency

Comparison of Performance Metrics

When evaluating the performance of single girder and double girder 20 ton overhead cranes, several key metrics come into play:

- Lifting Speed: Double girder cranes typically offer faster lifting speeds compared to single girder designs, thanks to their robust construction and superior power-to-weight ratio. This increased lifting speed can lead to enhanced productivity and efficiency in lifting operations.

- Precision: Both single and double girder cranes can offer high levels of precision in load handling. However, double girder cranes may have a slight edge in terms of stability and control, particularly when lifting heavy or bulky loads. This precision is crucial in applications where accuracy is paramount, such as precision manufacturing or material handling.

- Load Capacity: As mentioned earlier, double girder cranes have higher load capacity handling capabilities compared to single girder designs. This means they can handle heavier loads with ease and efficiency, making them the preferred choice for heavy-duty lifting applications.

Efficiency Considerations

Efficiency considerations encompass factors such as power consumption, maintenance requirements, and overall operational efficiency:

- Power Consumption: Double girder cranes may consume slightly more power than single girder designs due to their larger size and higher load capacity. However, advancements in crane technology have led to improvements in energy efficiency for both types of cranes, minimizing energy consumption while maximizing performance.

- Maintenance Requirements: Single girder cranes are often touted for their simplicity and ease of maintenance. With fewer components and a more straightforward design, they typically require less maintenance compared to double girder cranes. However, regular maintenance is essential for ensuring optimal performance and prolonging the lifespan of any overhead crane.

- Overall Operational Efficiency: Operational efficiency encompasses various factors, including uptime, downtime, and overall productivity. While both single and double girder cranes can offer high levels of efficiency when properly maintained and operated, double girder cranes may provide superior performance and reliability, particularly in heavy-duty applications.

By considering these performance and efficiency metrics, along with other factors such as application requirements and budget constraints, you can make an informed decision when selecting the appropriate overhead crane design for your specific needs. In the next section, we'll delve into safety considerations, highlighting the importance of safety features and regulations in overhead crane operations. Stay tuned as we continue our exploration of overhead crane solutions.

Safety Considerations

Impact of Design Differences on Safety Features

The design differences between single girder and double girder 20 ton overhead cranes can significantly impact safety features and considerations:

- Structural Integrity: Double girder cranes typically offer enhanced structural integrity compared to single girder designs. This increased stability and load-bearing capacity contribute to a safer lifting environment, particularly when handling heavy or bulky loads.

- Control and Precision: The design of double girder cranes allows for greater control and precision in load handling operations. This can help minimize the risk of accidents and injuries by ensuring smooth and accurate movement of loads, even in challenging conditions.

- Safety Devices: Both single and double girder cranes are equipped with various safety devices and features to prevent accidents and protect personnel and equipment. However, double girder cranes may incorporate additional safety features, such as redundant braking systems and overload protection, to enhance safety during lifting operations.

Safety Regulations and Standards Applicable to Both Designs

Safety regulations and standards play a crucial role in ensuring the safe operation of overhead cranes, regardless of design. Some of the key regulations and standards applicable to both single and double girder 20 ton overhead cranes include:

- Occupational Safety and Health Administration (OSHA) Regulations: OSHA sets forth regulations and standards for the safe operation of overhead cranes, including requirements for operator training, equipment inspection, and maintenance procedures.

- American National Standards Institute (ANSI) Standards: ANSI publishes standards for overhead crane design, operation, and maintenance, including guidelines for load capacity ratings, safety devices, and structural requirements.

- Crane Manufacturer Specifications: Crane manufacturers often provide specific safety guidelines and recommendations for their equipment, including proper installation procedures, maintenance schedules, and operator training requirements.

By adhering to these safety regulations and standards, employers can ensure the safe operation of single and double girder 20 ton overhead cranes, minimize the risk of accidents and injuries, and promote a safe working environment for all personnel involved in lifting operations. Check main safety devices and protection devices for 20 ton overhead cranes and 20 ton bridge cranes.

Case Studies and Projects for Your Reference

Case Studies Illustrating the Use of Single and Double Girder Designs

- Manufacturing Industry: A manufacturing company faced the challenge of efficiently moving heavy machinery components within its facility. After careful evaluation, they opted for a single girder 20 ton overhead crane due to its versatility and cost-effectiveness. The crane proved instrumental in streamlining production processes and improving workflow efficiency.

- Warehouse Operations: A logistics company required a lifting solution for loading and unloading cargo in their warehouse. They chose a double girder 20 ton overhead crane to meet their heavy-duty lifting requirements. The crane's robust construction and high load capacity enabled them to handle large and bulky loads with ease, enhancing operational efficiency and productivity.

Examples Highlighting Successful Implementations

- Steel Mill Application: A steel mill implemented a double girder 20 ton overhead crane to handle the transportation of steel coils within its facility. The crane's superior load capacity and stability proved crucial in safely moving heavy loads across the production floor, minimizing downtime and improving overall efficiency.

- Construction Site Usage: On a construction site, a single girder 20 ton overhead crane was utilized for lifting and positioning construction materials such as steel beams and precast concrete panels. The crane's compact design and maneuverability made it ideal for navigating tight spaces and meeting the project's lifting requirements with precision and reliability.

These case studies and real-world examples highlight the versatility and effectiveness of both single and double girder 20 ton overhead cranes across various industries and applications. By understanding the specific needs and challenges of each scenario, companies can make informed decisions when selecting the most suitable crane design for their operations.

20 ton overhead crane with custom design, 10 ton + 10 ton

20 Ton double girder overhead crane with open winch trolley for sale

Single girder overhead crane 20 ton for stone processing line

Decision-Making Process

Factors to Consider When Choosing Between Single and Double Girder Designs

- Load Capacity Requirements: Evaluate the weight and size of the loads to be lifted to determine whether a single or double girder crane is better suited for your needs.

- Span and Height Requirements: Consider the available space and lifting height in your facility to ensure compatibility with the selected crane design.

- Operational Environment: Assess factors such as frequency of use, operational conditions, and environmental factors to determine the most suitable crane design for your specific application.

- Budget Constraints: Take into account upfront costs as well as long-term maintenance and operational expenses when making your decision.

- Safety Considerations: Prioritize safety by ensuring compliance with relevant regulations and standards and selecting a crane design that incorporates appropriate safety features.

Evaluation Criteria for Selecting the Most Suitable Design

- Load Capacity: Determine the maximum weight and size of the loads to be lifted to ensure compatibility with the selected crane design.

- Space Constraints: Consider the available space in your facility, including ceiling height and clearance requirements, to determine whether a single or double girder crane is more suitable.

- Operational Efficiency: Evaluate factors such as lifting speed, precision, and overall operational efficiency to determine which crane design best meets your productivity goals.

- Cost-Effectiveness: Compare upfront costs, maintenance requirements, and operational expenses to determine the most cost-effective solution for your budget.

- Safety Features: Assess the safety features and capabilities of each crane design to ensure compliance with relevant regulations and standards and minimize the risk of accidents and injuries.

By carefully considering these factors and evaluation criteria, you can make an informed decision when choosing between single and double girder 20 ton overhead crane designs. Remember to prioritize safety, efficiency, and cost-effectiveness to select the most suitable crane design for your specific needs and requirements.

Conclusion

Summary of Key Differences Between Single and Double Girder 20 Ton Overhead Cranes

In summary, the choice between single and double girder 20 ton overhead cranes hinges on several key differences:

- Load Capacity Handling: Double girder cranes offer higher load capacity handling capabilities compared to single girder designs, making them ideal for heavy-duty lifting applications.

- Space and Height Requirements: Single girder cranes are more compact and suitable for facilities with limited space or lower ceiling heights, while double girder cranes provide greater lifting heights and clearance for taller loads.

- Structural Differences: Double girder cranes boast enhanced structural integrity and stability, making them more suitable for handling heavy or bulky loads with precision and control.

- Performance and Efficiency: Double girder cranes typically offer faster lifting speeds and greater operational efficiency compared to single girder designs, albeit at a higher initial investment.

- Safety Considerations: Both crane designs incorporate safety features, but double girder cranes may offer additional safety benefits due to their robust construction and stability.

Recommendations for Selecting the Appropriate Design

When selecting between single and double girder 20 ton overhead crane designs, consider the following recommendations:

- Assess Your Load Requirements: Determine the weight, size, and frequency of the loads to be lifted to determine the appropriate load capacity handling capabilities required.

- Evaluate Space and Height Constraints: Consider the available space and lifting height in your facility to ensure compatibility with the selected crane design.

- Prioritize Safety: Choose a crane design that incorporates appropriate safety features and complies with relevant regulations and standards to minimize the risk of accidents and injuries.

- Consider Long-Term Costs: Factor in upfront costs as well as long-term maintenance and operational expenses when evaluating the overall cost-effectiveness of each crane design.

- Consult with Experts: Seek guidance from crane manufacturers or industry experts to help assess your specific needs and requirements and make an informed decision.

By carefully considering these factors and recommendations, you can select the most suitable design for your specific lifting applications and operational requirements.

Thank you for joining us on this journey through the world of single and double girder 20 ton overhead cranes. We hope this guide has provided valuable insights and guidance to help you make informed decisions when selecting the right overhead crane design for your needs. If you have any further questions or require assistance, don't hesitate to reach out to us or consult with a qualified crane specialist. Happy lifting!

Main Projects

Related Products

22/5 Ton Overhead Crane Double Hook System: Robust double girder crane with 22-ton main and 5-ton auxiliary hooks for heavy lifting. Get double hook crane!

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch